Pre-Sales

Since the battery pack of new energy vehicles is placed on the chassis of vehicle, there are many opportunities to contact the environment and rainwater, while it needs to be disassembled and used for a long time. TY-640 is a medium-hardness silicone foam product developed and produced according to the application needs of battery sealing of new energy vehicles, and has passed a full range of customer application tests and market inspections.

Physical property | Testing standards | TY-640 |

| Color | Visualization | Gray, Black |

| Thickness(mm) Tolerance(%) | ASTM D374/D374M / | 0.8~20 ±10 |

| Density (kg/m3) | ASTM D1056 | 400 |

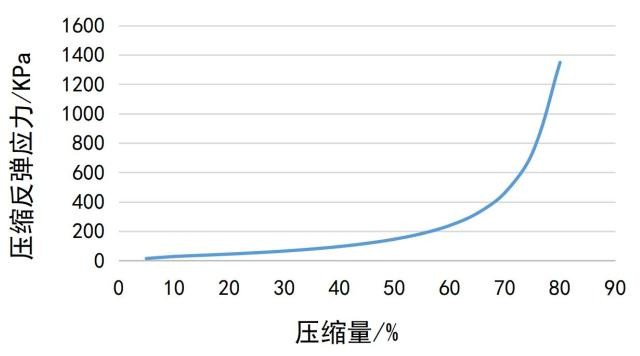

| Compression-Rebound Stress (kPa,25%) | ASTM D1056 | 80 |

| Permanent Compressive Deformation (%) | ASTM D1056 Test D@70℃ ASTM D1056 Test D@100℃ | <1 <5 |

| Tensile strength (kPa,Minimum) | ASTM D412 | 300 |

| Elongation at break(%,Minimum) | ASTM D412 | 80 |

| Thermal Conductivity(W/(m·K)) | ASTM E1461 | 0.064 |

| Volume resistivity (Ω·cm) | ASTM D257 | >1013 |

| Flame-retardant Rating | UL 94 | V-0,HF-1 |

| Recommended operating temperature(℃) | SAE J-2236 | -55~200 |

The above data is the average value of the overall test. Please contact our company for more technical information.

Compression rebound curve