Pre-Sales

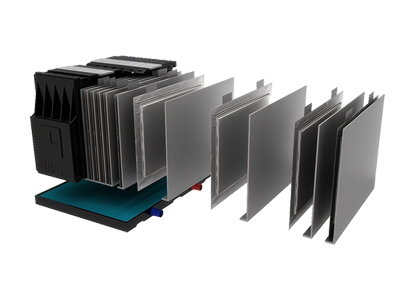

The TZ series is designed with a stronger bubble structure and more interconnected openings, so that the material can maintain a stable and consistent resilience under long-term compression, and can play the role of a spring in a small space, thus providing long-lasting and reliable support and cushioning for the equipment. TZ series silicone foams are available in different thicknesses and are easy to be processed into the required size.

Physical property | Testing standards | TZ-300 | TZ-400 | TZ-500Z | TZ-600 |

| Color | Visualization | Gray, Black | |||

| Thickness(mm) Tolerance(%) | ASTM D374/D374M / | 0.8~20 ±10 | |||

| Density(kg/m3) | ASTM D1056 | 350 | 400 | 500 | 550 |

| Compression-Rebound Stress (kPa,25%) | ASTM D1056 | 50 | 80 | 110 | 150 |

| Permanent Compressive Deformation(%) | ASTM D1056 Test D@70℃ ASTM D1056 Test D@100℃ | <1 <5 | |||

| Tensile strength (kPa,Minimum) | ASTM D412 | 280 | 300 | 400 | 600 |

| Elongation at break(%,Minimum) | ASTM D412 | 90 | 80 | 70 | 90 |

| Water absorption rate(%) | ASTM D1056 | 10 | 5 | 3 | 3 |

| Thermal Conductivity(W/(m·K)) | ASTM E1461 | 0.071 | 0.064 | 0.076 | 0.08 |

| Electrical Strength ROHS(kV/mm) | ASTM D149 | 5.04 | 6.40 | 7.45 | 4.50 |

| Volume Resistivity(Ω·cm) | ASTM D257 | >1013 | >1012 | ||

| Flame-retardant Rating | UL 94 | V-0,HF-1 | |||

| UL Yellow Card File Number | / | / | E516170 | / | |

| Recommended operating temperature(℃) | SAE J-2236 | -55~200 | |||

The above data is the average value of the overall test. Please contact our company for more technical information.

Compression rebound curve: